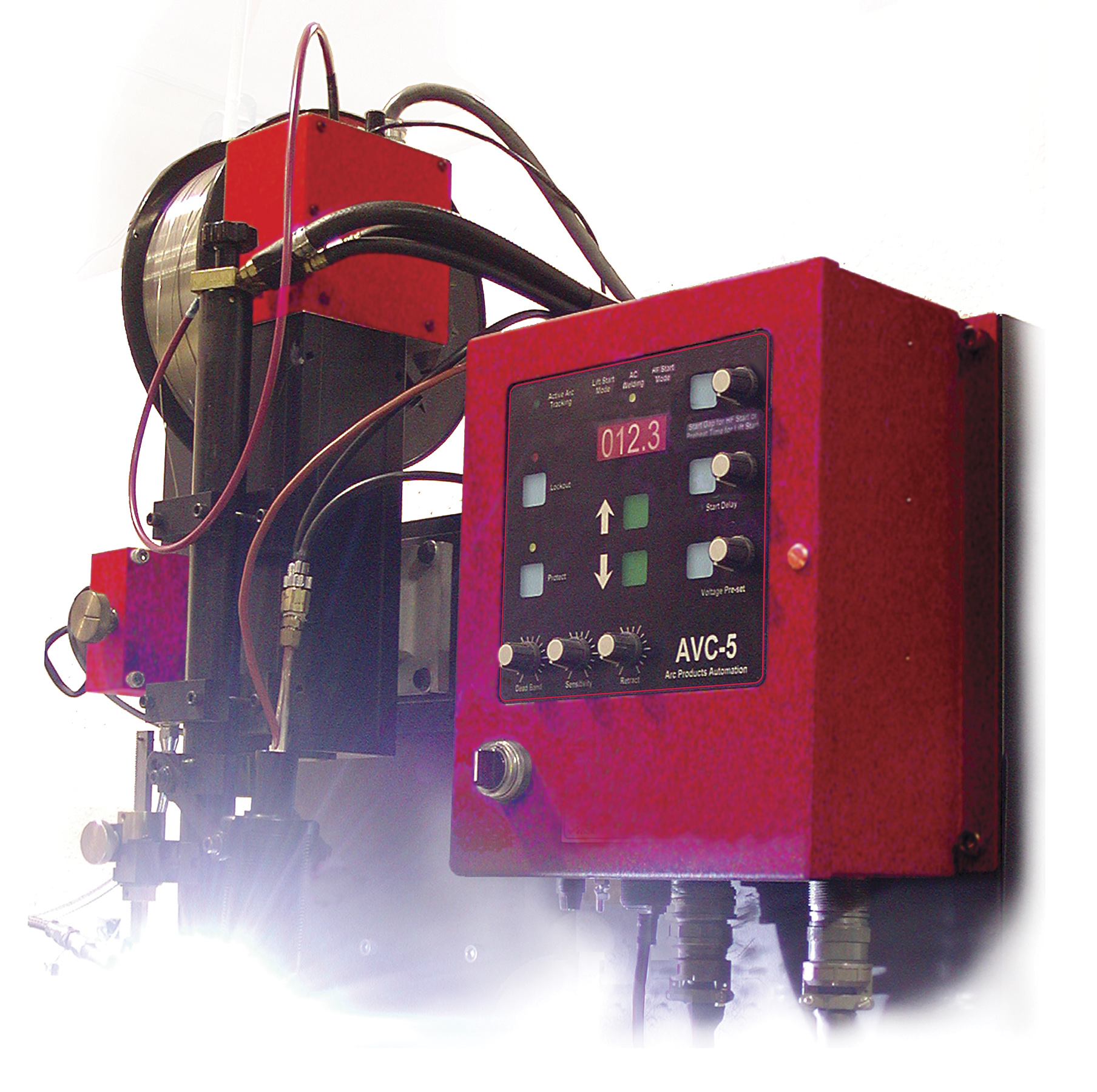

AVC-5 Arc Voltage Control System

Precise control of torch height for the most stringent industries.

AVC-5 Systems utilize a control and drive unit to maintain precise TIG arc length in automated systems. In long automated welds, the drive counteracts tungsten erosion, keeping the weld zone and heat input consistent throughout the length of the weld. The system is easy to operate and integrates with a wide range of power supplies, torches, and positioners for assembling turn-key automation systems.

K52200-1 AVC-5 ARC VOLTAGE CNTL SYS (replaces 0600-0100)

Includes:

- AVC-5 CONTROL UNIT ASSY

- AVC-5 6IN DRIVE ASSEMBLY

- CABLE ASSY AVC REM INT 10FT

- AVC-5 REM INT CABLE 10FT AUX

Ready to order or have additional questions? Give us a call today at 1-619-628-1022.

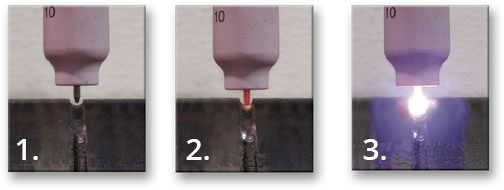

Lift-Start Process

Our patented Lift-Start™ process enables reliable, automated, non-HF (non high-frequency) arc starting on all metals. Upon touching the work piece, the tungsten is preheated for an adjustable time unique to the diameter of the electrode and the type of material being welded. This provides a smooth, consistent arc start, minimizing tungsten inclusion.

- TORCH LOWERS TO WORKPIECE

- TUNGSTEN PREHEATS

- SMOOTH, CONSISTANT ARC START

AVC-5 Arc Voltage Control Features and Benefits

- Start Delay, 0.1 – 9.9 seconds

- Standard or Lift-Start arc starting options

- Starting Arc Gap, 0.01 – 0.09 in. (0.25 – 2.28 mm)

- Deadband Adjustment, from ± 0.1 to 1.5 volts

- Sensitivity Adjustment, 0 to 100%

- Voltage Range, 5 – 50 VDC

- Adjustable Retract Distance, 0 to 12 seconds

- Lockout Switch and Indicator

- Auto-Tracking Indicator

- Digital Display

- Manual Up / Down Jog Switch on the control and drives

- Panel / Remote Switch for Arc Voltage Preset

- Burn-Through Detection

- 110/220V, 50/60Hz Input

STANDARD DRIVE UNIT

- Stroke Length: 6.5 in.

- Compensation Rate: 22 ipm max

- Manual Rate: 12 ipm

- Load Capacity: 45 lbs. at center of torch

- Net Weight: 15 lbs.

- Dimensions: 18 in. x 3 1/2 in. x 5 1/2 in.

WATCH IT IN ACTION

The AVC-5 Arc Voltage Control System has an accuracy of ± 0.1 volts, providing precise and consistent torch to work distance. This high accuracy compensates for tungsten erosion on long automated applications such as tube and pipe mills, keeping the weld penetration and heat input consistent throughout the length of the weld. Because of the high demand for throughput from a tube or pipe mill where welding speeds are quite often in excess of 10 feet (3 meters) per minute, the AVC-5 system removes the torch-to-work distance responsibility from the operator. As welding technology advances and weld speeds continue to push the envelope, our AVC-5 System will be at the forefront of maintaining torch height accuracy.

AVC-5 Control unit features a microcontroller-based unit with advanced capabilities in a simple-to-operate package. Capable of welding in AC and DC applications, the system can be used to weld mild steel, as well as many alloys. The system is hardened against High-Frequency damage and can be used in continuous High-Frequency (HF) AC welding applications. In addition to High-Frequency (HF) Arc starting capabilities, the AVC-5 System offers non-HF starting method known as Lift-Start™, taking full advantage of newer welding power source’s technologies.

One control unit works with either of our AVC drive assemblies. Our standard drive assembly is our most common drive with 6.5 inches (16.5 cm) of stroke and a 40 pound (18 kg) lifting capacity. It easily stands up to the harsh GTAW and PAW welding environments. If physical constraints exist in your welding area and our standard AVC Drive assemblies won’t fit, our Compact AVC Drive Assembly will. The Compact AVC Drive assembly is designed to fit inside of pipe and other small areas such as a weld box on a tube mill. Our Compact AVC Drive Assembly is also capable of lifting 40 pound (18 kg), but with a much smaller stroke of one inch (2.54 cm), making it ideal for tight spaces.

The AVC-5 Arc Voltage Control system can be configured to become the master weld sequence controller for a welding station. Controlling the welding power source, carriage control / rotation device and other components of the welding station eliminates the need for costly PLC equipment and programming. Add our AVC-5 system to your existing equipment and you can obtain higher welding speeds and better weld quality with a relatively small capital expense. The system typically pays for itself in six to eight months.

The control Unit can also be used with older drive assemblies built by Cyclomatic, which include the Standard AVC-3 and Standard AVC-4 Drive assemblies and the Compact AVC Drive assembly, provided these drive assemblies are in good working order.

If you’re still not sure if the AVC-5 is right for you, give us a call at 1-619-628-1022

Gas Tungsten Arc Welding (GTAW) and Plasma Arc Welding (PAW) applications are some of the most stringent in the welding industry. Whether you are welding products for the Aerospace or Aviation industry, welding tube or pipe in mills or welding pressure vessels, torch-to-work distance is a critical aspect of the process to create quality welds and maintain productivity. The torch-to-work distance is critical to maintaining consistent penetration and power (heat) into the part. Precise control of the torch height is the true function of our AVC-5 Arc Voltage Control System. In precision Gas Tungsten Arc Welding (GTAW) and Plasma Arc Welding (PAW) applications, our AVC-5 Control system maintains a consistent torch- to-work distance by monitoring the arc voltage and adjusting the torch up or down. Arc voltage and the torch-to-work distance are proportional, i.e., if the torch-to-work distance increases, the arc voltage also increases. By monitoring the arc voltage and comparing it to the preset desired welding voltage, the AVC-5 Arc Voltage Control system can precisely control the torch height.

ORDERING INFORMATION

K52200-1 AVC-5 ARC VOLTAGE CNTL SYS (replaces 0600-0100)

Includes:

- AVC-5 CONTROL UNIT ASSY

- AVC-5 6IN DRIVE ASSEMBLY

- CABLE ASSY AVC REM INT 10FT

- AVC-5 REM INT CABLE 10FT AUX

Ready to order or have additional questions? Give us a call today at 1-619-628-1022.

ADDITIONAL PRODUCT DETAILS AND OPTIONS

![]() AVC-5 Arc Voltage Control Product Brochure

AVC-5 Arc Voltage Control Product Brochure

SUPPORT

![]() AVC-5 Arc Voltage Control Operations and Service Manual (201327-001C) Download

AVC-5 Arc Voltage Control Operations and Service Manual (201327-001C) Download