DirectArc™

Magnetic Arc Control Systems

Accurate control of arc oscillation for the most rigorous industries.

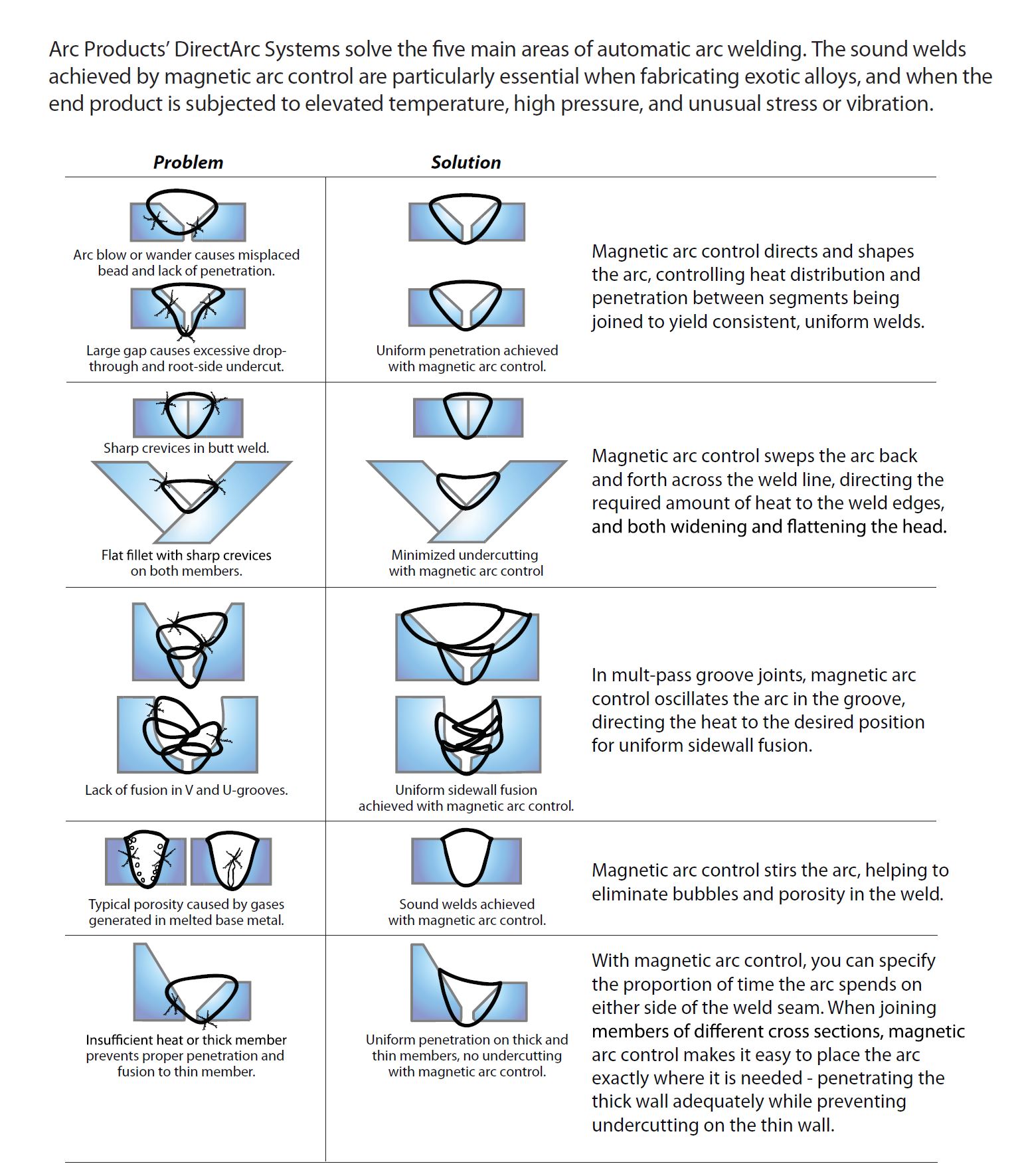

MA-20 and MA-40 DirectArc™, magnetic arc control systems utilize a control and water-cooled magnetic probe mounted at the torch to provide complete control of the TIG arc. Depending on the application, the systems can counteract arc blow, drag and wander, increase penetration, reduce porosity, or smooth the weld puddle. The system is easy to program and integrates with a wide range of power supplies, torches, and positioners for assembling turn-key automation systems.

With Arc Products’ DirectArc™ Systems, you can precisely position, weave, or stabilize the welding arc in any pattern you require. It’s an ideal solution for thick-to-thin material, wide weld joints, and high-speed TIG welding, drawing out impurities and creating cosmetic finishes.

Features

- Multiple controls and probes offer precise solutions to various weldment challenges

- Water-cooled probe

- Controls heat distribution on thick-to-thin material

- Minimizes undercut

- Reduces porosity

- Improves penetration

- Stirs the weld puddle to refine grain structure

- Integrates with DWF-4 and AVC-5

MA-20 Arc Control

Our most popular controller, the MA-20 features a PWM power supply and adjustable oscillation speeds from seven per minute to 30 per second. Independently controlled left and right dwell settings create a weave effect, allowing maximum flexibility when working with an uneven work piece. A stabilize/oscillate switch allows you to disable the speed and dwell controls while the position and amplitude controls remain operative. Final taper gradually reduces magnetic field during welding down-slope.

All probes include simple, secure mounting provisions and can attach to most welding torches in minutes. Water-cooling hoses (where required) and probe cables are part of each probe assembly. See the controller/probe compatibility chart for system details.

MP-1 Probe

The MP-1 is a single-tip, water-cooled probe that adapts to conventional torches. The MP-1 works well in tight clearances and is primarily used to weave the arc across the seam or to stabilize the arc.

MP-2 Probe

The dual-tip MP-2 slips over a conventional TIG torch and can be used either for cross-seam weaving or in-line weaving. In-line weave is primarily used in tube mills to preheat the tube, giving increased weld travel speeds.

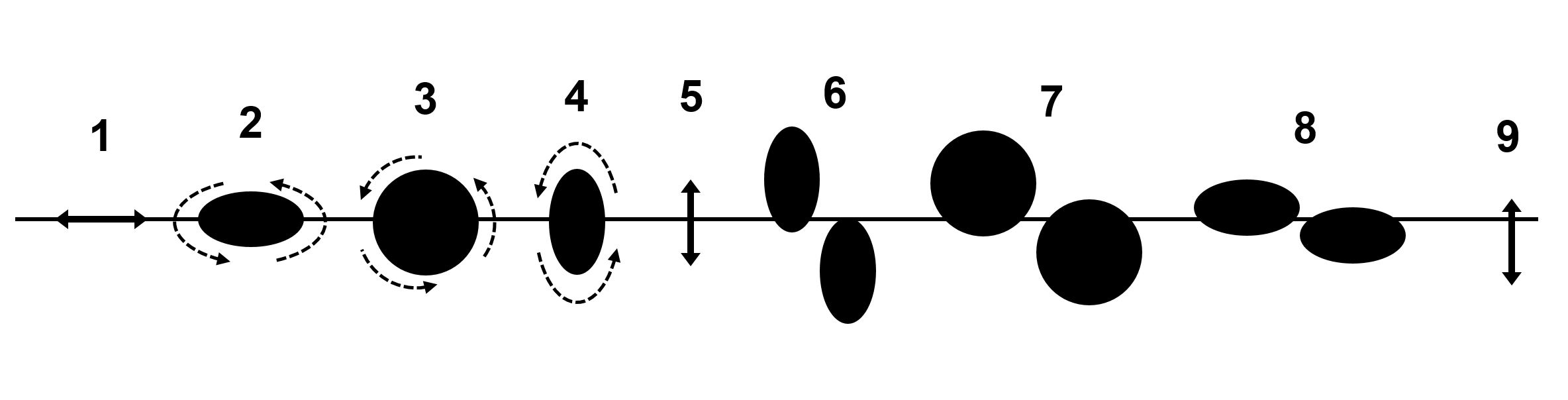

MA-40 Arc Pattern Control

This unit adds a new dimension to magnetic arc control – pattern control. With the MA-40, the welding arc can be shaped, widened or narrowed as required. The rapid, controlled motion of the arc stirs the molten puddle for a noticeable reduction in porosity and improvement of the grain structure in the weld.

The MA-40 Control Unit provides two-axis magnetic arc control with independent amplitude and position control for each axis. A stabilize mode with amplitude and position control adjustments is also available for one-axis oscillation.

All probes include simple, secure mounting provisions and can attach to most welding torches in minutes. Water-cooling hoses (where required) and probe cables are part of each probe assembly. See the controller/probe compatibility chart for system details.

MP-4 Probe

With four independently controlled magnetic coils, the MP-4 probe is the most flexible for weld bead profiling. It is used with the MA-40 control unit only. The Arc Products MA-40 Control Unit and MP-4 Probe provide the ability to shift the entire arc pattern relative to the weld seam with position controls.

The MA-40 Control Unit and MP-4 Probe provide the ability to shift the entire arc pattern relative to the weld seam with position controls, as shown below.

|

|

- Straight line oscillation along seam

- Elliptical pattern along seam symmetrical

- Circular pattern symmetrical

- Elliptical pattern across seam symmetrical

- Straight line oscillation across seam

- Elliptical pattern across seam offset

- Circular pattern offset

- Elliptical pattern along seam offset

- Straight line oscillation across seam offset

| MA-20 Arc Control | MA-40 Arc Control | |

| Dimensions | 9.75″ x 4″ x 11.75″ | 9.75″ x 4″ x 11.75″ |

| Sweep Frequency | 0-30 osc./sec. | 0-30 osc./sec. |

| Sweep Amplitude | Proportional to arc length (approx. 1:1) | Independent adjustment for each axis, proportional to arc length (approx. 1:1) |

| Arc Position | Proportional to arc length (approx. 1:1) | Independent adjustment for each axis, proportional to arc length (approx. 1:1) |

| Dwell Ratio | 1:1 to 100:1 on either side of weld seam | N/A |

| Dwell Control | Independently variable left and right | N/A |

| Shaping | N/A | Independent adjustment for each axis, proportional to arc length (approx. 1:1) |

| Final Taper | 0-15 sec. | 0-15 sec. |

| Shipping Weight | 12 lbs. | 12 lbs. |

| Probe Model | Shipping Weight | Max. Field Strengh | Controller Compatibility |

| MP-1 | 5 lbs. | 300 gauss max | MA-20 |

| MP-2 | 4 lbs. | 300 gauss max | MA-20 |

| MP-22 | 7 lbs. | 600 gauss max | MA-20 |

| MP-4 | 5 lbs. | 300 gauss max | MA-40 |

| MP-100 | 4 lbs. | 600 gauss max | MA-20 |