MULTI-PROCESS WELD HEADS

DESIGNED FOR PIPE AND FLAT TRACK WELDING

Introducing the HELIX® M627 digital clamp-on weld head. It is the latest addition to the HELIX® M series weld heads, the next generation of weld heads for mechanized welding. They’re not only lightweight and durable, but also very easy to install and position on the track or directly to the pipe.

The HELIX M series tractors provide a flexible solution to easily switch torches for GTAW, Hot Wire GTAW, GMAW and FCAW processes. Designed for the harshest FCAW applications while keeping the accuracy needed for TIG and hot wire TIG, the HELIX M series tractors are all-around high performers.

FEATURES and BENEFITS

- Plug and play connectivity with APEX 3 Series controllers

- Common adjustments are tool-less

- Touch points are highlighted in red for easy learning

- Rapid work connection with tracks or integral clamp

- Simple control cable based on digital communications

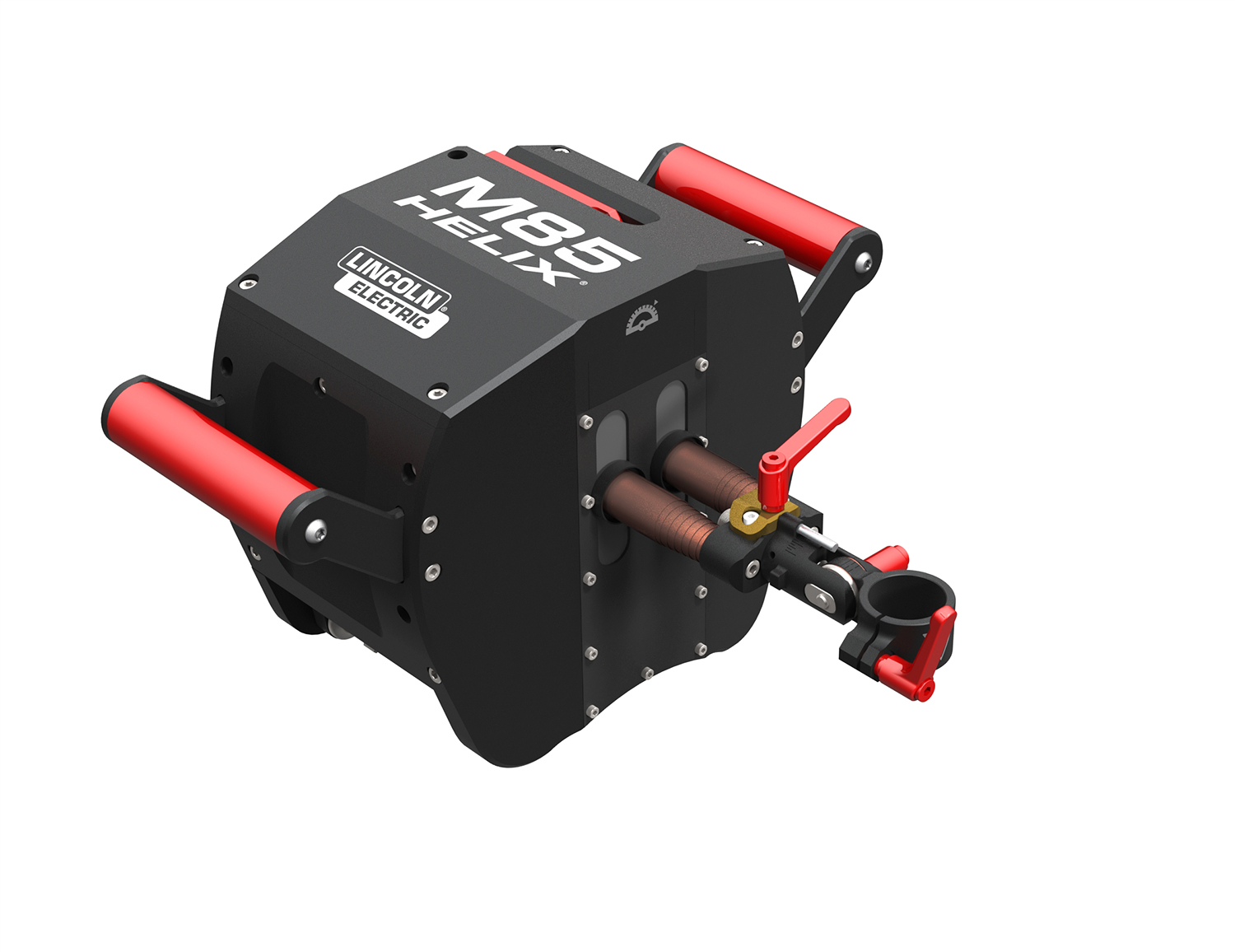

Built for applications with limited axial clearance, the HELIX M85 weld head can do it all. Based on digital communications and robust hardware, the M85 weld head can perform a wide variety of welds. The steep learning curve that is required with most other orbital equipment is minimized due to simple design. All of the motors and harnesses are packaged inside the weld head, reducing visual confusion when working in the shop and providing protection from harsh environments when out in the field.

Designed to be as light weight and compact as possible without sacrificing durability, its low axial clearance enables welding close to flanges and other obstructions near the joint. Major upgrades can be simply accomplished with limited technical capability due to the digital nature of the weld head. The weld head also incorporates an inclinometer permitting advanced repeatability and automatic weld parameter changes during the weld process. To add onboard wire-feeding capability, only a simple Allen wrench is required. Everything else just plugs in line with the common control cable.

The HELIX M45 weld head allows for 45 degrees of outward and inward adjustment. It can be quickly be clamped on to an orbital or flat track. In addition, the operator has multiple toolless torch adjustment options, giving greater control of the weld puddle for more complex welds. With a low radial clearance of 4.5 in. (114 mm), the HELIX M45 weld head allows for digitally controlled, precision welding in areas of limited space and physical constraints. This lower profile weld head was designed so it can be quickly set up as far as five inches (127 mm) from the weld joint without affecting oscillation, offering greater flexibility.

Designed on the Power Wave® platform for advanced, multi-process capabilities, this device also features a pivoting torch height assembly which provides perpendicular height control to the puddle face. Optional on-board wire feeders are also available for GMAW / FCAW and GTAW welding applications. The weld head also incorporates an inclinometer permitting advanced repeatability and automatic weld parameter changes during the weld process.

The HELIX M627 weld head allows for tight radial clearance applications on pipe from 6″ and down. With a low radial clearance of 2.7 in. (67 mm), the HELIX M627 weld head allows for digitally controlled, precision welding in areas of limited space and physical constraints.

Designed on the Power Wave® platform for advanced, multi-process capabilities, this device also features travel, height, and oscillation controls along with onboard wire feeding for precise tungsten and wire location.

The weld head also incorporates an inclinometer permitting repeatability and automatic weld parameter changes during the weld process.